How to Assemble a Lithium Battery Pack: Step-by-Step

Feb 9, 2025 · Assembling a lithium battery pack requires careful planning, the right tools, and a thorough understanding of series and parallel configurations. By following this step-by-step

STANLEY® Assembly Technologies for High-Performance

Cordless Torque Tools offering transducer-controlled battery powered tools that are ideal for threaded fastening assembly. STANLEY ® delivers improved productivity and quality with

Symmetric Cells as an Analytical Tool for Battery Research: Assembly

Feb 15, 2023 · The demand for a better battery in the aspect of performance, cost, and scalability has significantly driven the development of new electrode chemistries. The electrochemical

Lithium-Ion Battery Assembly Process & Key

May 17, 2025 · The lithium-ion battery assembly process is a sophisticated, multi-layered operation that relies heavily on precision, quality, and cutting-edge

Lithium-Ion Battery Pack Manufacturing Process

Jun 4, 2025 · Discover how lithium-ion battery packs are made—sorting, welding, assembly, BMS integration, and testing—to deliver reliable power for EVs,

Innovating battery assembly

Aug 13, 2025 · Increased assembly complexity with live battery components and multiple operations requires special procedures, equipment and tools. Diferent product variants in the

The Essential Guide to Equipment for Lithium Battery Assembly

Feb 11, 2025 · This guide will explore the essential equipment needed for lithium battery assembly, covering everything from the basic tools to more sophisticated machinery.

Symmetric Cells as an Analytical Tool for Battery

Symmetric Cells as an Analytical Tool for Battery Research: Assembly, Operation, and Data Analysis Strategies Zilai Yan*,z Andlinger Center for Energy and the Environment, Princeton

Battery Rebuild Service | Interstate All Battery Centers

There''s no need to let your trusty old cordless tool go when it no longer holds a charge, and a replacement battery is too costly or hard to find. Let a trained professional at an Interstate All

Lithium-Ion Battery Pack Manufacturing Process

Jun 4, 2025 · Each phase plays a critical role in ensuring the performance, safety, and reliability of the battery module. With proper attention to quality and

Assemble Lithium Battery: Step-by-Step Guide, Tools,

Learn how to assemble a lithium battery by yourself with our step-by-step guide. Discover the essential tools, materials, and safety precautions needed for successful assembly. Our

Essential Equipment for Lithium Battery Assembly: Tools,

Apr 24, 2025 · The growing demand for lithium batteries across electric vehicles, consumer electronics, and energy storage systems has made equipment for lithium battery assembly

6 FAQs about [Tool Battery Assembly]

What is battery assembly?

Battery assembly is the process of assembling parts to create a functioning battery. This involves combining essential components like cells and connectors. Using the right tools and following precise steps is necessary to ensure the battery works properly.

What tools are used in battery assembly?

Purpose: These tools facilitate safely handling and manipulating battery cells during assembly. Examples: Tweezers, vacuum pens, and cell holders ensure precise positioning and prevent contamination. Importance: Proper handling tools minimize the risk of damage to sensitive battery components and ensure assembly accuracy.

What are battery cell handling tools?

Battery Cell Handling Tools Purpose: These tools facilitate safely handling and manipulating battery cells during assembly. Examples: Tweezers, vacuum pens, and cell holders ensure precise positioning and prevent contamination.

How do you assemble a battery?

Once you have all the parts, tools, and knowledge, assembling a battery involves carefully connecting the cells in the desired series and parallel configuration, ensuring each cell is balanced and protected by the BMS, and securely packaging the assembly to withstand use and transportation.

What is battery pack assembly process?

Battery Pack Assembly Process Component Preparation: High-quality battery cells, BMS, wiring, and casings are inspected and prepared for assembly. Cell Assembly: Battery cells are arranged in series or parallel configurations to achieve the required voltage and capacity.

What tools do you need for a battery pack?

Other Tools: Various other tools are going to be needed depending on the complexity of the battery pack, including cutters for the conductive materials, and a heat gun for applying heat shrink wrap. Cell Holders or Frame: To prevent short circuits and manage heat effectively, cells must be properly spaced using cell holders or a custom frame.

Update Information

- Tool battery lithium battery modification

- Single power tool lithium battery

- Energy storage battery assembly precautions

- Battery cabinet assembly plant

- Moscow high quality power tool lithium battery

- How much is the new Avalu tool battery

- Outdoor energy storage battery assembly

- Tool battery charging voltage

- 30 000 mAh tool battery

- Brazilian electric tool lithium battery

- Slovenia power tool lithium battery manufacturer

- Lithium battery assembly cylindrical

- Quick assembly of lithium battery pack

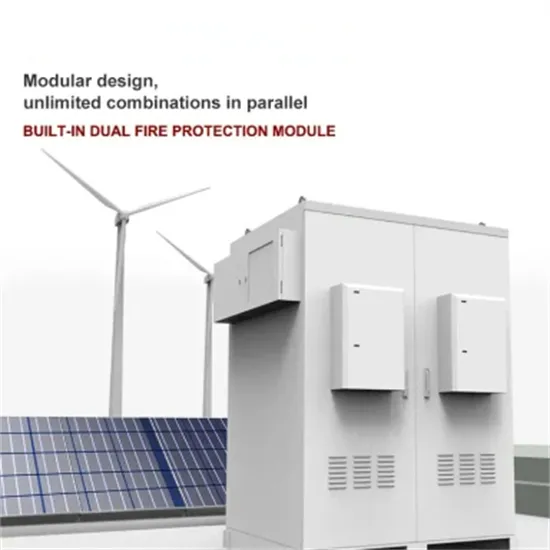

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.