Effects of Years of Operation of Photovoltaic Panels on the Composition

Soil bacterial community composition and diversity can be an important bioindicator for assessing ecosystem stability, and photovoltaic (PV) shading is a key factor influencing soil bacterial

Composition of photovoltaic panels

Solar panels consist of photovoltaic (PV) cells which produce electricity through a process known as the photovoltaic effect. PV cells convert sunlight into electrical energy and are typically

Photovoltaic panel composition structure

Apr 27, 2024 · Composition and Structure: Cadmium telluride solar panels are thin-film photovoltaic devices that convert sunlight directly into electricity through the photovoltaic

The Composition of the Solar Panel and the Function of Each

Solar panels are also called solar modules and solar panels. The assembly of multiple solar cells is the core part of the solar power system and the most important part of the solar power

Characterising the composition of photovoltaic panels

Feb 16, 2023 · This work is designed to characterise the chemical composition of end-of-life photovoltaic panels from different manufacturers to record the variability between different

(PDF) Recycling of Solar Panels: Sustainable Disposal of Photovoltaic

Jul 9, 2024 · Abstract This paper provides a thorough examination of the recycling process for solar panels and the environmentally-friendly disposal of photovoltaic (PV) elements.

Composition of photovoltaic panels

Feb 27, 2023 · Solar panels consist of photovoltaic (PV) cells which produce electricity through a process known as the photovoltaic effect. PV cells convert sunlight into electrical energy and

Solar panel components, the structure of PV panels

Feb 25, 2016 · The most crucial component of the solar panels is the photovoltaic (PV) cells responsible for producing electricity from solar radiation. The rest of

Understanding the Composition of a Solar Cell

1 day ago · Discover the 7 essential components of solar panels, how they work together, and what to look for when choosing quality panels. Expert guide with testing data.

Experimental analysis of dust composition impact on Photovoltaic

Jan 1, 2024 · Solar Photovoltaic systems are greatly influenced by meteorological conditions of the surrounding area, dust is the most influencing one. Dust deposition on the surface of

Dust impact on photovoltaic modules: Global data,

Oct 1, 2024 · The dust accumulation on the PV surface impacts the electrical, optical, and thermal characteristics of PV modules by obstructing the sunlight, which leads to a decrease in

A technical review of crystalline silicon photovoltaic module

Oct 1, 2024 · It dwells deep into the current recycling processes available for crystalline silicon (c-Si) solar panels. It explores the composition of PV modules and provides a detailed analysis of

The Composition of the Solar Panel and the Function of Each

Ⅰ. About the solar panel Solar panels are also called solar modules and solar panels. The assembly of multiple solar cells is the core part of the solar power system and the most

What Are Solar Panels Made of? Discover Their

Feb 6, 2024 · However, thin-film panels tend to have lower efficiency and shorter lifespans compared to crystalline silicon panels. Comparison of Composition

Types of photovoltaic solar panels and their

Nov 6, 2017 · Photovoltaic solar panels are devices specifically designed for the generation of clean energy from sunlight. In general, photovoltaic panels are

Overview of life cycle assessment of recycling end-of-life photovoltaic

Jan 1, 2024 · The current status and challenges of second-life PV modules include people''s doubts about renovating photovoltaic panels, lack of professional maintenance personnel, and

A review of toxicity assessment procedures of solar photovoltaic

Feb 15, 2024 · Environmental management of solar photovoltaic (PV) modules is attracting attention as a growing number of field-operated PV modules approach end of l

6 FAQs about [Photovoltaic panels composition]

What are solar panels made of?

Most panels on the market are made of monocrystalline, polycrystalline, or thin film ("amorphous”) silicon. In this article, we'll explain how solar cells are made and what parts are required to manufacture a solar panel. Solar panels are usually made from a few key components: silicon, metal, and glass.

What are photovoltaic cells?

Photovoltaic cells are the most critical part of the solar panel structure of a solar system. These are semiconductor devices capable of generating a DC electrical current from the impact of solar radiation.

What are solar photovoltaics made of?

Solar photovoltaics are made with several parts, the most important of which are silicon cells. Silicon, atomic number 14 on the periodic table, is a nonmetal with conductive properties that give it the ability to convert sunlight into electricity.

What is a solar panel?

About the solar panel Solar panels are also called solar modules and solar panels. The assembly of multiple solar cells is the core part of the solar power system and the most important part of the solar power system.

What percentage of solar panels are monocrystalline?

Percentage of a monocrystalline solar panel: 5.2% Polysilicon, made from silicon metal, is the key material used to make solar cells. This is because its semiconducting properties allow it to convert sunlight into electricity (i.e. the photovoltaic effect).

How are monocrystalline solar panels made?

Monocrystalline solar panels are produced from one large silicon block in silicon wafer formats. The manufacturing process involves cutting individual wafers of silicon that can be affixed to a solar panel. Monocrystalline silicon cells are more efficient than polycrystalline or amorphous solar cells.

Update Information

- Photovoltaic panels are installed under solar lights

- Can photovoltaic panels generate electricity continuously

- How much does the north-facing orientation of photovoltaic panels affect power generation

- Photovoltaic panels installed on roofs in Turkmenistan

- Venezuela enterprise solar photovoltaic panels

- Photovoltaic panels that can be directly installed on the roof

- 6 100w monocrystalline photovoltaic panels in parallel

- Are communication base stations equipped with photovoltaic panels

- Tiraspol Sloped Roof Photovoltaic Panels

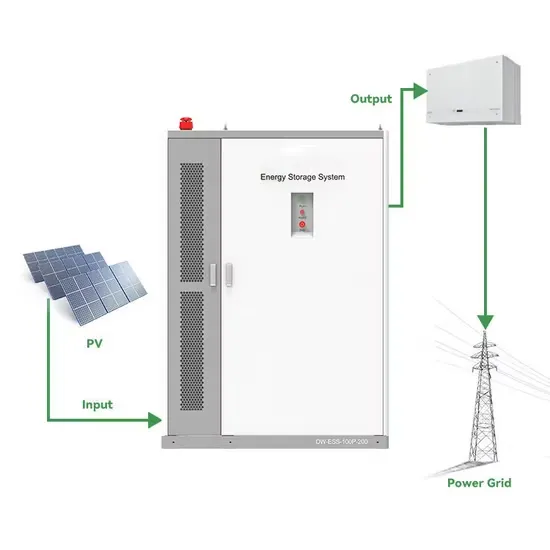

- 5 photovoltaic panels plus energy storage

- Installing solar photovoltaic panels in Funafoti

- Production of home solar photovoltaic panels

- 50What is the size of photovoltaic panels

Solar Storage Container Market Growth

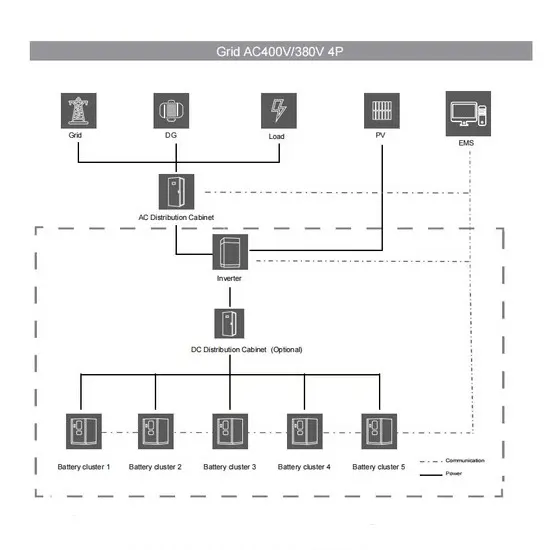

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.