to Hydrogen Gas Safety Part I: Industrial Storage

Feb 7, 2023 · The main hazards with hydrogen storage and handling are specific to the physical and chemical properties innate with hydrogen including a wide flammability range, low ignition

SAFETY IN STORAGE, HANDLING AND DISTRIBUTION

Aug 7, 2025 · This publication applies to the layout, design and operation of fixed storages and the transportation of liquid hydrogen in bulk form by tankers or tank containers, by road, sea

An overview of hydrogen storage technologies

Oct 1, 2024 · This comprehensive review paper provides a thorough overview of various hydrogen storage technologies available today along with the benefits and drawbacks of each

How to transport and store hydrogen facts and figures

May 27, 2021 · » HOW TO TRANSPORT AND STORE HYDROGEN – FACTS AND FIGURES ENTSOG, GIE and Hydrogen Europe have joined forces on a paper that answers a number of

Review of common hydrogen storage tanks and current

Mar 1, 2024 · Due to the technical complexity of the liquid form storage and the material-based storage, the current FCEVs are dominated by the compressed hydrogen gas system, which

Hydrogen Storage and Transportation

Oct 4, 2024 · For large-scale industrial gas storage and transportation, businesses often use MEGC containers and tubetrailer solutions. These containers store and transport hydrogen in

Shipping container for the transport of hydrogen (ADR)

Aug 15, 2025 · Hydrogen shipping containers are designed for maximum safety and efficiency. Special materials are used to ensure resistance to corrosion and mechanical damage. These

Current Practices to Transfer and Deliver Liquid Hydrogen

Mar 29, 2022 · • Significant experience in North America and Europe delivering hydrogen Systems were sited and built per NFPA 55 (and NFPA 2) Transportation equipment meets

Hydrogen Storage and Transport Beyond Pipelines:

Dec 22, 2023 · CAN/BNQ 1784-000 [101] defines the installation requirements for hydrogen generating equipment for non-process end use, hydrogen utilization equipment, hydrogen

Overview of the Container Safety Ordinance

Jun 29, 2017 · * No color coding ordinance on the compressed hydrogen containers for vehicle fuel systems and the international compressed hydrogen storage containers for vehicle fuel

Container Hydrogen Energy Storage Standards

What are the standards for hydrogen storage & transportation? Standards for hydrogen storage and transportation published by ISO, CGA, NFPA, ASME, ANSI, SAC, CEN and JISC cover

Hydrogen Container And Emergency Generator – H2Storage

A standard shipping container, see picture opposite, containing tenfold of high pressure tanks and all necessary tubing and appendages. The container can be implemented to store large

SAFETY IN STORAGE, HANDLING AND DISTRIBUTION

May 6, 2024 · A liquid hydrogen storage installation on a user''s premises is defined for the purpose of this code of practice (COP) as the installed liquid storage tank. This COP applies to

HYDROGEN PEROXIDE PRODUCERS SAFETY STANDARD:

Oct 28, 2019 · INTRODUCTION As an active member of the North American Peroxide Producers Safety Committee, Solvay Chemicals, Inc. actively participated in the development of these

A comparative analysis of the regulations, codes and standards

Feb 7, 2024 · In order to promote the application of hydrogen storage cylinder, guide its design, manufacture, inspection and testing, a series of regulations, codes and standards have been

Hydrogen Storage and Transport Beyond Pipelines:

Dec 22, 2023 · This report provides recommendations for revisions of standards to accommodate scaled-up means of hydrogen transportation and storage, as new solutions are emerging in

An overview on the technologies used to store hydrogen

Oct 1, 2023 · Hydrogen can be stored to be used when needed and thus synchronize generation and consumption. The current paper presents a review on the different technologies used to

Development of Standards for Hydrogen Storage and

Standards for hydrogen storage and transportation published by ISO, CGA, NFPA, ASME, ANSI, SAC, CEN and JISC are reviewed and analysed in this paper. Numbers of standards for

A comparative analysis of the regulations, codes and standards

Feb 7, 2024 · GB/T 42612 is established for refillable type IV hydrogen storage cylinders used on road vehicles for the storage of compressed hydrogen gas as a fuel, while the hydrogen

Standard SOLID-H™ Hydrogen Storage Containers

Nov 26, 2024 · SOLID-H™ Model CL-370A metal hydride hydrogen container holds 370 standard liters of hydrogen gas. Like all SOLID-H™ containers, it has a pressure relief valve for safety

6 FAQs about [What is the standard for container hydrogen storage ]

What are the standards for hydrogen storage and transportation?

Abstract. Hydrogen storage and transportation are the intermediate link of hydrogen production and the point of end-use. Standards for hydrogen storage and transportation published by ISO, CGA, NFPA, ASME, ANSI, SAC, CEN and JISC are reviewed and analysed in this paper. Numbers of standards for hydrogen embrittlement are more than the others.

What are the regulations for hydrogen storage cylinders?

For the past two decades, some regulations, codes and standards are issued for hydrogen storage cylinder, such as EC REGULATION 406 , UN GTR13 Phase 1 (GTR13-PH1) , CSA/ANSI HGV2 , GB/T 35544 , SAE J2579 , ISO 19881 and GB/T 42612 .

What is hydrogen transport & storage?

The transport and storage of hydrogen is a mature industry, focused primarily on industrial processes requiring hydrogen, which rely on existing codes, standards, and regulations.

What is a hydrogen storage cylinder?

Hydrogen storage cylinder is an important component in high-pressure gaseous hydrogen (HPGH2) storage system, and plays a key role in hydrogen-powered transportation including land vehicles, ships and aircrafts. Over the past decade, the number of hydrogen fuel cell vehicles (HFCVs) has rapidly increased worldwide.

How can hydrogen be stored underground?

The last method for underground storage of large quantities of hydrogen is a lined rock cavern. This consists of constructing a storage cavern with a lining of gas-tight steel encased in a layer of concrete. The use of casing-lined depleted oilfield wells is similar.

What are the different types of hydrogen standards?

CGA standards cover the and supply systems. NFPA 2 covers fundamental gaseous hydrogen and cryogenic liquid hydrogen. NPFA containers, cylinders and tanks. GB standards pro vide hydrogen storage devices and systems. Table 1. General design and safety standards for hydrogen devices, containers, storage buffers, etc. As is shown in

Update Information

- What does a standard energy storage container look like

- What is large container energy storage

- Which standard should energy storage container refrigeration meet

- What are the battery energy storage container systems

- Standard container energy storage cabinet

- What is the energy storage container manufacturer

- What brands of energy storage container manufacturers are there

- What are the container energy storage plants in Estonia

- Nassau Hydrogen Fuel Cell Energy Storage Container

- What are the Freetown container energy storage battery manufacturers

- What are the contents of container energy storage business

- What are the container energy storage companies in Benin

- What are the container energy storage businesses

Solar Storage Container Market Growth

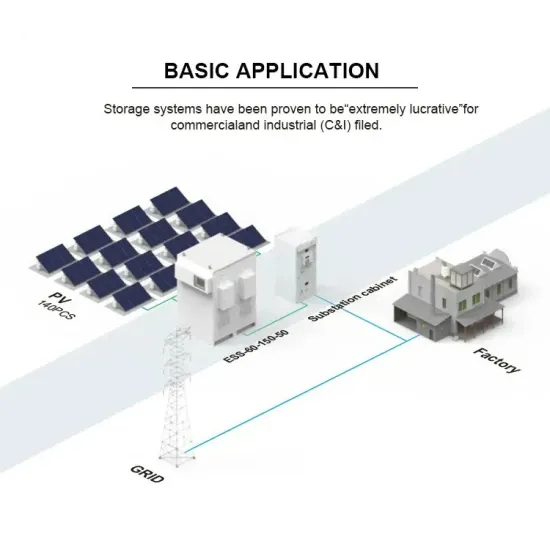

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.